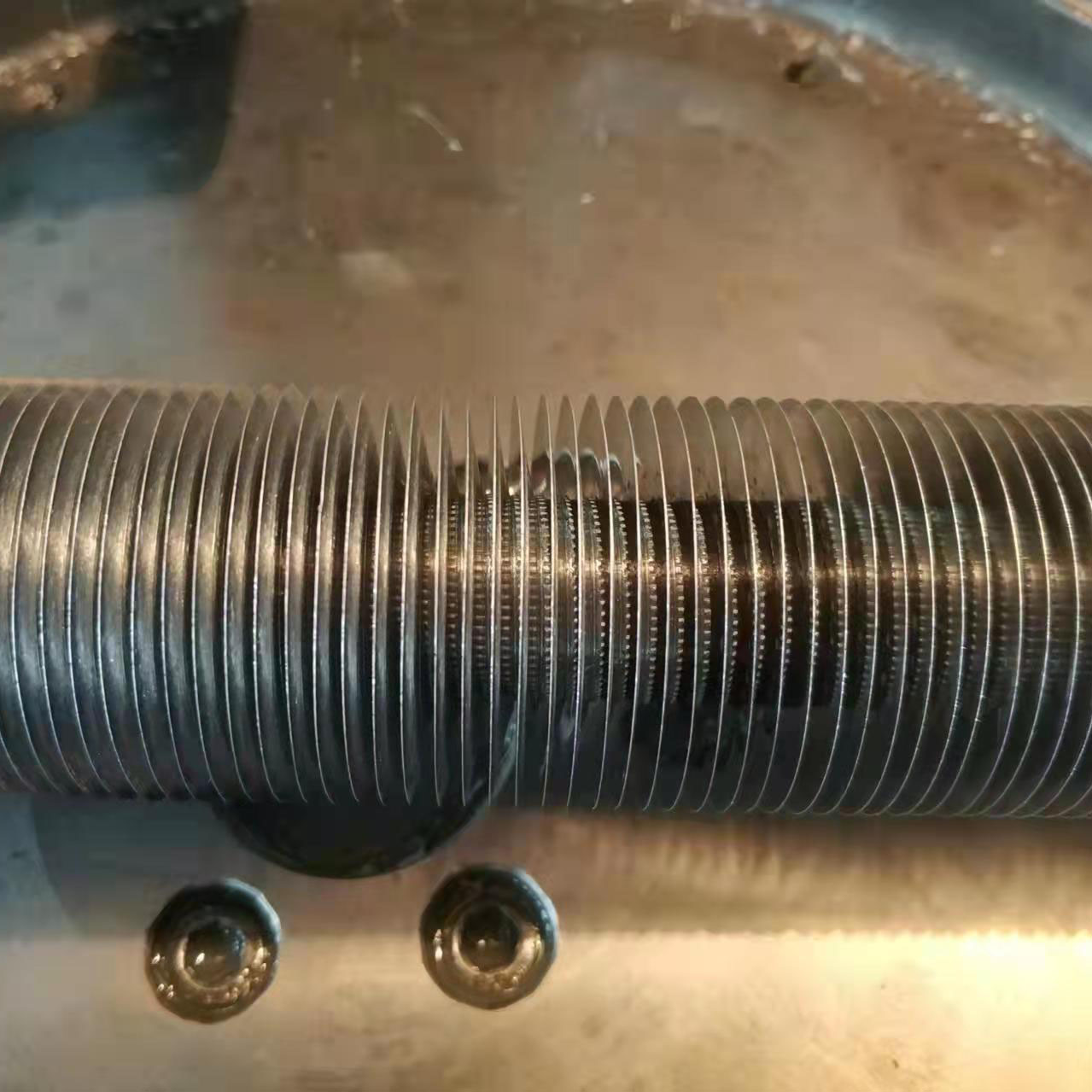

Factory wholesale Copper Tube Fin Heat Exchanger - Stainless Steel Alloy Steel Serrated Finned Tube – Datang

Factory wholesale Copper Tube Fin Heat Exchanger - Stainless Steel Alloy Steel Serrated Finned Tube – Datang Detail:

● Higher heat transfer coefficient. The serrate can make the gas flow across the fins freely, enhancing the turbulent motion and improving the heat transfer effect. Researches show that serrated fin tube’s heat transfer efficiency is about 15-20% higher than common solid fin tube.

● Reduce metal consume. Due to the higher heat transfer coefficient, for the same amount of heat, serrated fin tube is with less heat transfer areas, which help reduce the metal consume.

● Anti-ash-deposition and anti-scaling. Due to the serrate, it is very hard for the serrated fin tube to deposit the ash and scaling.

● It is more flexible to adapt to the changes of gas flow direction.

● The important features of this configuration are efficient, effective bond of fin to tube under all conditions of temperature and pressure, and ability to withstand high fin side temperatures. This serrated fin configuration is even better to withstand the fin fouling if that is a problem in the application. This gives better heat transfer properties compared to solid fins

Base Tube Details

1. Tube Diameter: 20 mm OD Min to 219 mm OD Max.

2. Tube Thickness: Minimum 2 mm up to 16mm.

3. Tube Material: Carbon Steel, Stainless Steel, Alloy Steel, Corten steel, duplex Steel, Super Duplex Steel, Inconel, High Chrome High Nickle & Incolloy, CK 20 material and some other material.

Fin Details

1. Fins Thickness: Min. 0.8 mm to Max. 4 mm.

2. Fins Height: Min 0.25” (6.35 mm) To Max.1.5” (38 mm).

3. Fin Density : Min 43 Fins per Meter to Max. 287 Fins per Meter.

4. Material: Carbon Steel, Stainless Steel, Alloy Steel, Carton steel, Duplex Steel.

Product detail pictures:

Related Product Guide:

The corporate upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will keep on to serve outdated and new clients from home and abroad whole-heatedly for Factory wholesale Copper Tube Fin Heat Exchanger - Stainless Steel Alloy Steel Serrated Finned Tube – Datang , The product will supply to all over the world, such as: Albania, Swiss, Argentina, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we've been committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have now passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!